The Challenge

Building an autonomous rover capable of navigating complex environments presented several key challenges that required innovative solutions across multiple engineering disciplines. The primary goal was to develop a system that could complete three distinct missions: navigating through obstacles, docking at specific stations, and dropping payloads at designated locations.

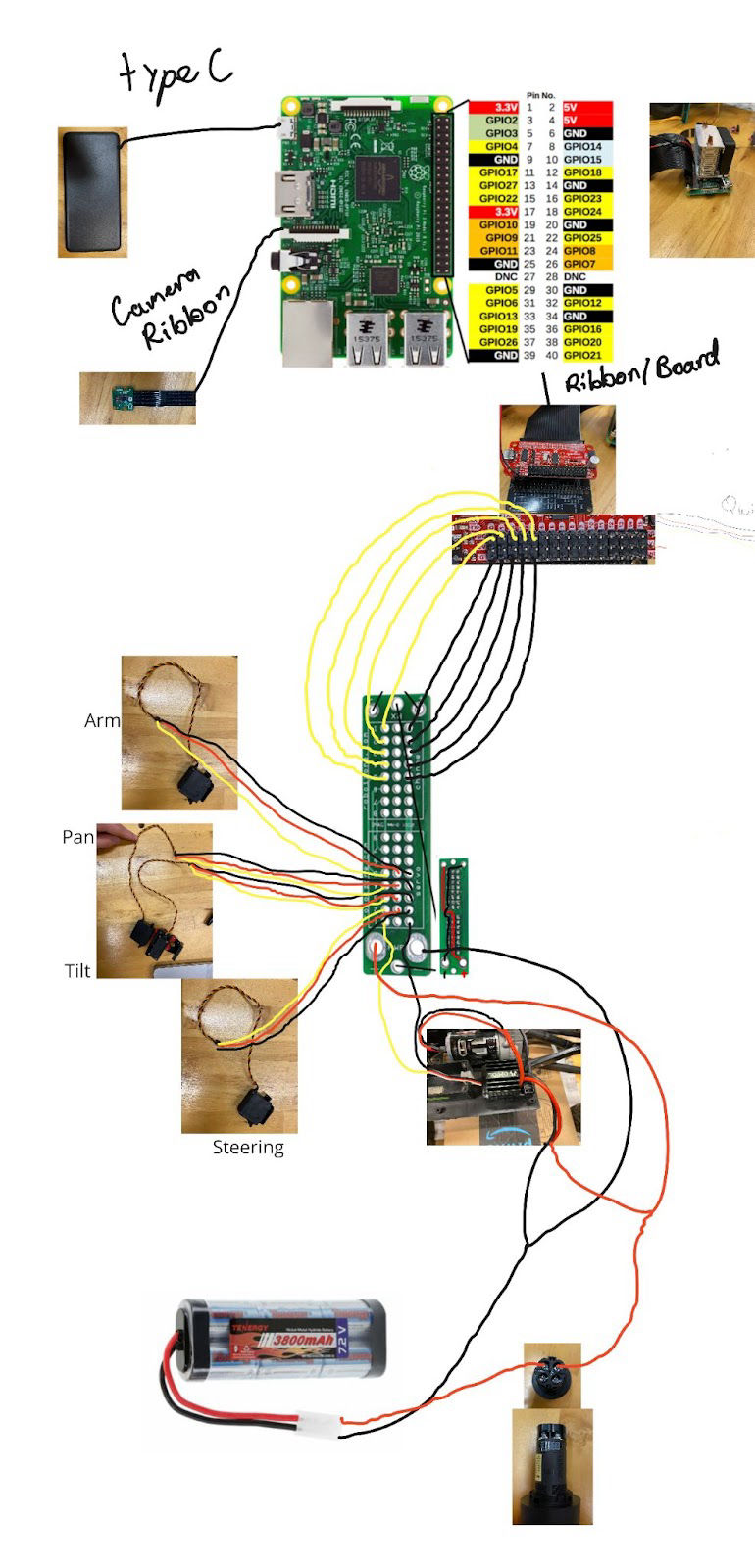

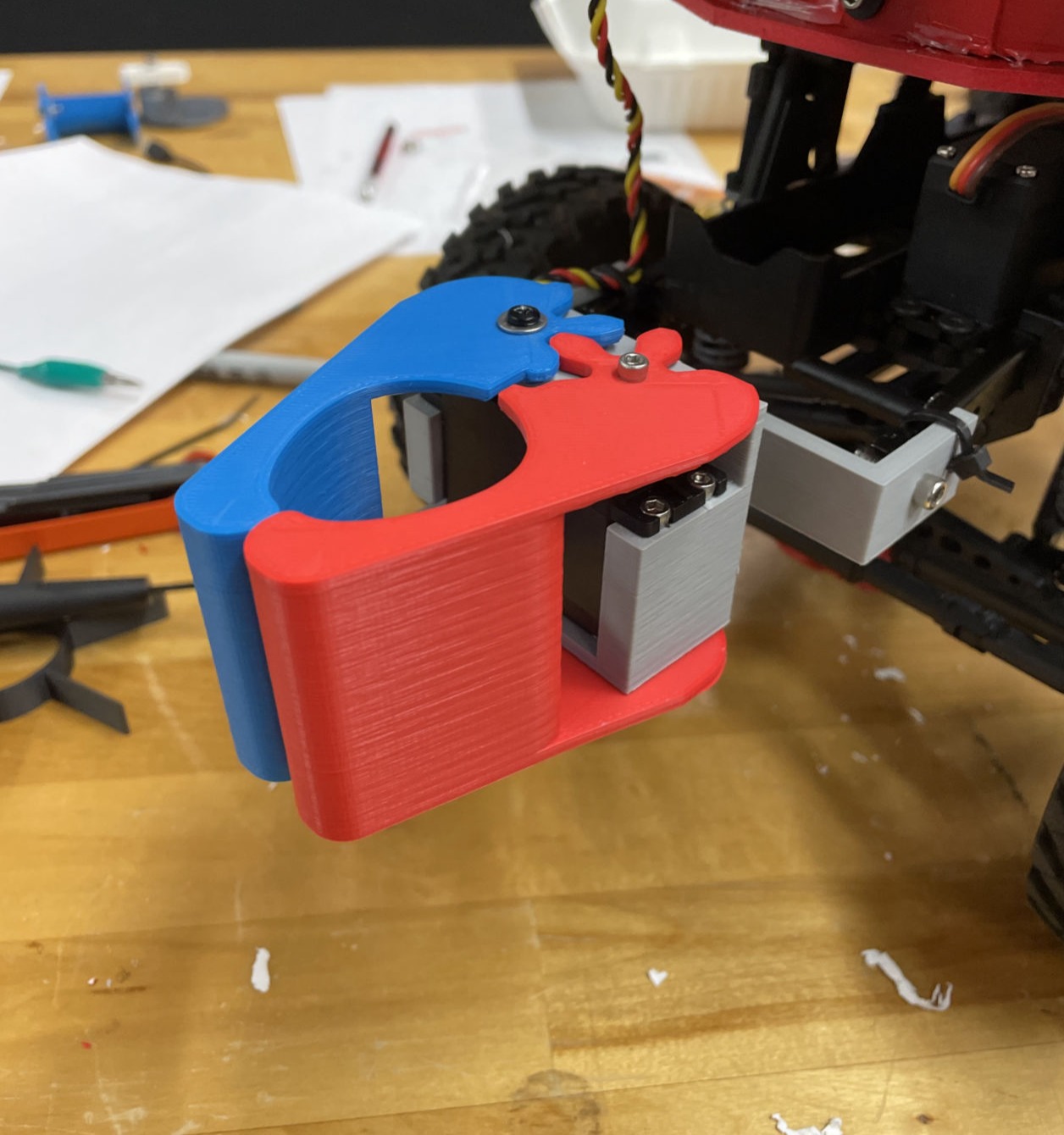

The rover needed reliable sensor integration for different environmental conditions, a robust control system for navigation in unstructured environments, and computer vision algorithms for path finding and April Tag detection. Additionally, it required a mechanical system that could carry payloads and operate reliably, along with a power distribution system that supported both logic and motor circuits.